When it comes to 2x140mm models a certain amount of lowered expectations come along for the ride. After all, this class in general is typically much easier on Ye Olde Budget than its bigger brothers and thus the entailment to the lower MSRP is a lower build budget for Arctic’s design team to work within. As such, things that would royally peeve us get a hall pass. This goes double when talking about the Arctic Liquid Freezer III 280… as there are air-based CPU cooling solutions that cost more than it does. You may feel differently and expect a 1-bill (USD) cooler to be premium in all shapes, and forms.

Thankfully, even if you are expecting the sun and demanding the moon be thrown in as a freebie, the ALF 3 280 will not (overly) disappoint. Sure. We still think the entire ALF 3 line-up should get a variant of the uber-fancy, extremely premium “Pyramid of Power” shipping container the flagship 420-class uses. Sure. We would love to see a wee bit more accessories be included (especially a plastic-based low Newton Meter “click style” Torque wrenches tool to help with the Intel ILM installation).

All that however is nit-picking.

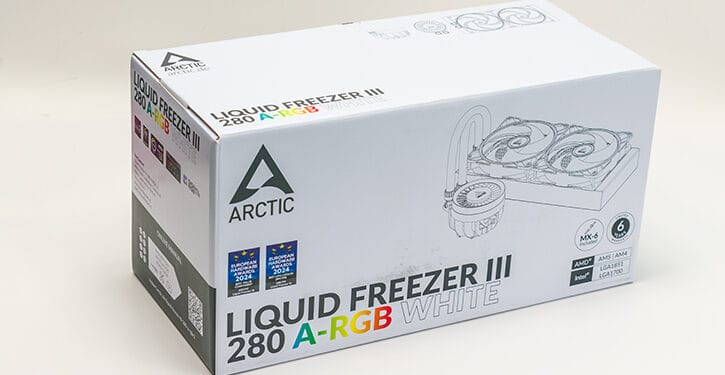

As with its 360-class brethren, the ALF 3 280 AIO’s shipping container is premium and comes with premium accessories. Where other companies consider it ‘good enough’ to give you a pretty cardboard box with good internal protection… Arctic goes above and beyond. Want a full-color photo and a diagram of the key components on the box so you can ‘get’ what you are buying before you buy? The ALF 3’s shipping container does that. Want multiple layers of cardboard protection that is better than what Asetek-based units come clad in? the ALF 3 does that too. Want an easy way to know what revision you are buying? The ALF 3 clearly states it on the bottom label.

Want the hot-swappable VRM fan to be as protected as the waterblock? The ALF 3’s box even does that too. Put simply, while we would love to see Arctic go even further and “above and beyond”… it is hard to really nitpick when talking about an AIO that is cheaper than the competition’s typical 240-class options and yet offers more than the competition’s 280-class models. We still will, but it is hard to get worked up over missing features when this 280 already offers more than any $100 AIO has any right to. Color us impressed.

Moving on.

Let us be clear. Yes. The 2x140mm radiator-based AIO class is smaller than the 360 class. Yes, it is approximately 2/3rds the size of the 420 class. Even yes. 280-class AIOs have garnered a sterling reputation for being easy to work with. None of that is the same as saying the Arctic Liquid Freezer III 280 is small. It is not. Nor is it a lightweight. To be precise this is a chunky 280 that weighs just as much as many a 360-class AIO. So please… use two hands when handling it as it will surprise you if you are used to 280s but not this 280.

The reason it is so heavy is because, just like the rest of the ALF 3 series, this bad boy makes use of a highly thick (38mm), highly robust, highly advanced radiator. So much so there is no direct AIO comparison for the ALF 3 280 to be made. Instead one has to look past All In One models and look at custom water loop radiators to find its equal (or better). Even then expect to throw out all those ‘ease of use’ arguments as nothing but a premium rad will outperform it.

To be precise, this All In One cooling solution uses what is pretty much a ‘double thick’ (~45mm) radiator… just in a “thick” 38mm z-height form factor. If that sounds like a contradiction in terms… it kinda is… or at least was before the wizards over at Arctic made fantasy a reality. No. We are not being hyperbolic. No. We do not mean that they have broken the laws of reality and made a tool that is ‘bigger on the inside’. Instead, this 38mm z-height “thick” 2×140 class radiator has the cooling performance (or at least potential) of that of a 45mm “double thick” class 2×140 radiator. Just without the baggage that double-thick rads are known for (and they are legion, for they are many).

As we went over in previous ALF 3 reviews, Arctic was able to do the seemingly impossible by… cheating. Hyperbole and jokes aside (as Arctic is known in certain circles for making excellent 27mm thick fans that compete against 25mm thick ones), Arctic took a look at what makes a radiator work, and then they asked a simple question “why?”. Then they threw out all their preconceived notions and proved to their own satisfaction what is and what is not still valid. That seemingly simple idea took a lot of time, effort, and money but Arctic’s management was willing to do it… to the glee of their engineering team who got paid to think outside the box.

However, to ‘get’ what they did a bit of background information is first required. With water cooling radiators the whole idea is to move water over a waterblock’s cold plate, efficiently transfer said heat to the water, then push this heated water through long, but narrow, water channels that in turn transfer the heat to the folded aluminum fin array hugging said channels… that then, in turn, transfer the heat to the air via the attached fans’ air movement. Sounds complex… because it is. Back in the early days of water cooling, it was quickly found that the area directly in front of the fan’s hub was a dead zone. AKA an area of the radiator where no air movement was possible. No air movement means no heat transference. No heat transfer means wasted potential and a bigger form factor is required to overcome these dead zones. To overcome this known issue “standoffs” were built into the radiator. As the name suggests these standoffs keep the fan from being mounted directly to the core… instead the fan ‘stands off’ from the core allowing air movement to cover the dead zone directly in front of a fan’s motor hub before being pushed through the folded aluminum cooling fins.

As an added benefit by moving the fans off the rad less static pressure is required to push the air through the fin array. Making it a win-win inclusion that quickly became the de-facto standard. Like everything else, in now ‘classical’ radiators, this standoff was standardized at between 5 and 6mm per side in the ‘standard’ (remember fans on the other side of the rad would suffer a similar fate as physics doesn’t care about push vs. pull). Thus a ‘thin’ 28mm rad has a cooling core of about 16 to 18mm thick, and a ‘thick’ has about 26 to 28 core… and a ‘double thick’ (~45mm) has about 33 to 35mm core.

This is where Arctic’s “heretical” approach to design enters the chat. Arctic’s engineers asked a simple question: why is the standoff standard set to a nominal 5.5mm? It was set to that because earlier fans were terrible. “Everyone knew” that 80mm was the pinnacle of radiator cooling performance, the 92mm form factor was pushing things… and 120mm fans? That was a compromise size, to say the least… and 140mm fans… oof… on a radiator? Fuhgeddaboudit! Thus, 140mm fans needed all the help they could get when it came to reducing the inherent static pressure of a radiator. Which in turn meant using a nominal (+/- 0.5mm) 5.5mm offset for the integrated ‘fan shroud’ / standoff.

As with its bigger bro’s the ALF 3 280 does not use that standard offset for its fan shrouds. Instead, it only has a nominal 3mm offset. This means the ALF 3’s 38mm overall z-height allows for a ~32mm z-height/thick cooling core to be used. Put another way it’s a rounding error away from entry-level ‘double thick’ radiators. This in turn means the ALF 3 2×140 should have similar to same cooling performance as a double thick ‘custom water cooling loop only’ 2x140mm radiator… just without (most of) the headaches those beefy double thick rads bring to the table.