Let’s start with the main claim to fame of the ALF series’ waterblock. The integrated fan. Yes, zee Swiss and zee German wizards over at Arctic long ago asked “why” when it came to the phenomena of rising motherboard temps when an AIO was used… and figured out it was due to lack of air movement. Air movement motherboard manufactures baked into their mobo’ design process as they assumed a downdraft cooler would be stuck on top of the CPU (as both Intel and AMD stock coolers are downdraft coolers). With Asetek (and 99.9999999 percent of the competition) this phenomena continues to this day. With Arctic they fixed this problem that motherboard manufactures refuse – to this day – to take responsibility for. They fixed it by sticking a fan on the end of the ‘block. Yes. A simple, effective, and paradigm shifting tweak that no one else even thought about doing… and yes it paid massive dividends for Arctic in the form of putingthe ALF 2 on the radar of many a mainstream buyer’s radar.

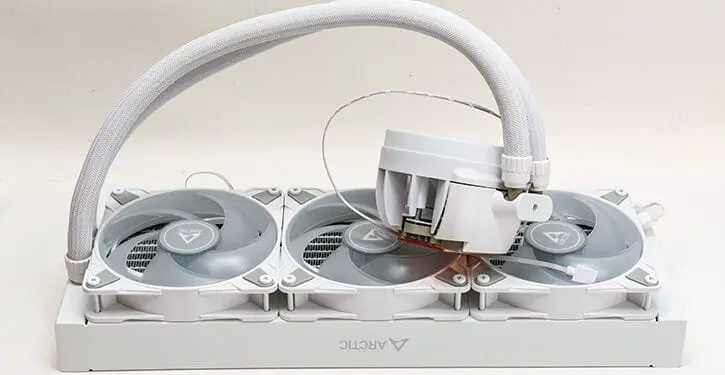

The downside was the small fan was loud, had to run at insane RPMs, and while it was better than nothing it was not precisely moving a ton of air. Between the ALF 2 and ALF 3 Arctic’s engineers again asked “why” they did what they did… and improved upon their first try at fixing the industry wide problem. The end result? They yeeted the ALF 2’s VRM fan and replace it with a fan that is both massive and easier to work with. To be precise the fan is not integrated into the block like the ALF 2’s and rather sits on top of the block. Allowing it to be as big as the block. Which in turn allows it move a veritable ton of air and do so at lower RPMS. This combination means even when run at 50% it can still allow even the most hoopity of VRM heatsinks on the cheesiest of motherboards to run cool as a cucumber.

Even more impressive is this mega-VRM cooling fan is now not only theoretically “end-user replaceable” but actually real-world end-user replaceable. So much so even a novice can do it. That is because, thanks to mounting magnets and a contact pins+pads for power transference, this bad boy pops on and off with ease. With such ease that Artic has you install it after you mount the block to your motherboard. This one-two combination of increased size of said fan with insane ease of use means this one feature is more than enough justification to stop buying ALF 2s and start buying ALF 3s. Yes. It really is that big of a deal.

Now with all that said. It still is not perfect… as Artic may have gotten a little too fancy with the new VRM cooler design. This configuration could easily do ~293 degrees of cooling coverage… yet in its current configuration only about 100-110’ish actually gets covered. The rest? Its physically blocked by the thermo-molded plastic fan housing of this big VRM fan. Which is a shame as this device could have easily offered active M.2 cooling. Which in the coming years could be a big enough feature to make 3rd party heatsinks a thing of the past, which in turn could have freed up ~20 bucks in the budget for other things. Like justifying a 360 instead of 280 ALF 3. Needless to say, hopefully a future revision will open up the VRM fan’s airflow zone and allow it to cool more than just VRM heatsink(s). In the meantime… a ¼ drill bit and a bit of time can get you in the same ballpark as the eventual official revision will. If you don’t mind voiding its warranty that is.

Moving on.

Excellent VRM cooling is a nice bonus, but a waterblock’s main reason for existing is being able to cool the CPU and properly push water through the radiator. This is especially true when talking about double thick rads and their insanely high static pressure requirements. Thankfully, and as we made mention previously, the ALF 3 series does not rely on a piddly little Asetek pump. Instead Arctic went full custom… and then in what is a recurring theme, after the ALF 2’s success asked ‘why’. Why was their pump good but not great… then fixed it.

Let’s start with the ALF 2 to show just how much Arctic has done in a single generation… and why other companies will be pressuring Asetek to fix their pump so as to be able to compete with this new European Beast. In the ALF 2, like 99.999999 of all AIOs, the pump for the waterblock is centrally located and was mounted in a horizontal orientation. As such water is sucked in from the inlet tube, forced to do a 90 degree bend, pushed through the pump’s small impeller, then another 90degree bend down to the micro-fin cooling plate level, then another 90 degree bend, forced through the copper cold plate, then another 90 degree bend and up and into the outlet tubing. That is a lot of 90 degree bends. Each 90degree bend in a loop increases friction (both “static” and “dynamic” pressure), which in turn makes it harder for the pump to push the water through the radiator and the cold plate.

Compared and contrast that with the ALF 3 and its vertically orientated (and bigger) pump. The water exits the inlet port, immediately enters (and cools) the water pump, then is pushed down to the micro-fin cold plate height, then and only then does it encounter a 90 degree bend… where it then flows over said microplate, slams into a second 90 degree bend… but then exits the waterblock via the outlet tube. Which is obviously fewer 90 degree bends. Which means less pressure required to push the water through all that tubing, water channels, and water block. Which in turn means less RPMs to hit said needed pressure and thus less wear and tear on the pump’s motor.

Thanks to modern living we can actually somewhat calculate this ‘head loss’ and give an even more precise estimate… somewhere between a Scientific Wish and a Sciencey Wild Arsed Guess. The water block cold plate is 40mm x 44mm in both (and for ease of calculation we are going to just say it’s a direct straight line for both). The tubing is 18inches / 457mm. Times 2 gives us 914mm. The rad is 360mm long with 7 inlet and 7 outlet water channels. Rounding we get about 3,434mm of ~6mm ID tubing length. Call it a flat 4K to account for a bit of the cold plate channels.

For waterflow, the ALF3 does have a bigger water pump compared to the ALF2 but its only pulling 4 watts of 12v power. Call it a decent 60 Liters per Hour (for point of reference a DC-LT can do 100LpH @ ~5 watts). Using a handy dandy online calculator (albeit with PolyEth for the tubing calculation) with the ALF 3 we get a friction loss of about 2/3rds of a PSI. Plunking in the ALF 2 numbers we get basically 3/4’ers of a PSI in static pressure the pump has to overcome. That is just for the 90 degree bends. AKA not including the water block’s micro-fin array’s impact, the water channels multiple Ts in the rad. Just the 90 degree bends in the water block. It might not sound like much, but that is a massive difference when talking about a (relatively) big loop with a (relatively) small pump.

Now if they would only stop worrying about block height so much, and put a big boi DDC equivalent pump into their loop, that would as an added bonus push the inlet/outlet ports up higher (and allow us to use big boi M.2 coolers), we would be truly impressed. Until that happens, or even going to a dual DD-LT equivalent (one on block, one next to the rad), all AIOs are not going to be as good as a legit custom water loop. Getting better every generation, but still plenty of room for improvement… even if this is about as good a pump as we have seen in any AIO to date.