As expected, the Alpine 17 LP’s shipping container is basically the same as any Alpine variant in recent memory. That is to say it is small, but eye catching in an understated way. As noted in the past, Artic is a rather conservative company at heart. So when they have a design, and color pallet, that not only works but can instantly be picked out as being an ‘Arctic’ product on a crowded store shelf… they are not interested change just for the sake of change. We have zero issues with this as a knowledgeable buyer will be able to pick it out in a heartbeat, and that self-same conservative aesthetic will also make novices be drawn to it.

Also like all previous Alpine models we can think of, the internal configuration consists of a piece of formfitting cardboard that locks(ish) the Alpine 17 LP in place and keeps it from moving around. Unlike with the Arctic Freezer i35 series we have no problems with this. After all, this is a cooling solution that costs less than some fans. Thus, this “good enough” configuration is just that: Good. Enough.

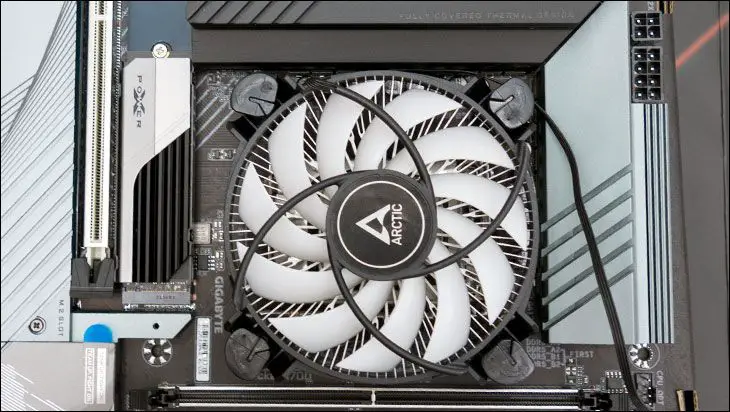

For anyone who has never even heard of, let alone seen, an Artic Alpine LP cooling solution they are rather easy to describe. Simply take a standard Alpine cooling solution of the same generation… and shrink down its Z-axis dimensions by thirty to fifty percent. Which in turn trims the weight down from a light 288g (~10.2oz) to a svelte ~183grams (~6.5oz).

In addition to making it much easier to handle, this change means that instead of an overall height of about 77mm, you can expect to find a cooling solution that is only ~53.5mm tall (or about 40% shorter). If one was to tear it down to into its two ‘base’ components… instead of a ~45mm fin array you would expect one that is 22.5 (or 22.67 by our calipers) or a shade under 50 percent of the standard Alpine 17’s fin array.

Instead of a 32 mike mike tall fan, one will find a ~21.5mm tall fan.

For those who are doing the math… none of those dimensions ‘add up’. To clear up the confusion the cooler + fan combination off the Arctic Alpine 17 LP add up to 44mm z-height. Not 53.5mm. The reason Arctic says its bigger is because Artic does not follow Intel measurement conventions when it comes to Z-Axis. So instead of measuring from the base of the heatsink to the top of the fan’s hub, like Intel and 99.9 percent of manufactures do, Artic starts at the tip of the pushpins and measures to the top of the fan’s hub. What that means is when installed this lilliputian cooler sits only 49mm above the motherboard. That is a mere 2mm taller than the Intel RS1’s uninstalled height specification. That is only ~12mm taller than what Corsair Vengeance DDR5 sit when they are installed. So, yes, that is indeed one short cooling solution… and why it is branded as a Low Profile model.

Make no mistake it is only the Z-axis that has changed. The X and Y stay the same at the maximum allowable (by Intel LGA 1700 keep-out specifications) 95 millimeters.

Put another way, the Alpine 17 LP follows firmly in the Alpine 12 LP’s footsteps… and the only major change is in the mounting brackets. Instead of mounting brackets with a lateral length of 75mm (aka LGA 1100 and LGA 1200 mounting hole specifications), it uses 78mm lateral offsets. Since Intel LGA 1700 CPUs have a slightly lower Z-height Artic has made the central portion of this LP’s fin array taller than on the Alpine 12 LP series. It is not much, at a mere 1mm difference… but it is a bit more aluminum for the fin array to make use of.

Sadly, the portion of the Alpine 17’s base that is solid also has not changed. It still is ~31.5mm in size. This was ‘fine’ back in the LGA 1200 days as a 37.5×37.5 IHS meant only a couple millimeters around the periphery of the CPU’s IHS was not covered. LGA 1700 CPUs are 37.5 x 45mm. Meaning that along the long axis there is a 3mm ‘gap’ on both sides, and along the two short edges there is a gap that is a whopping 6.75mm wide. That still is technically enough to cover the actual CPU hidden underneath the IHS… but Arctic really need to update their Alpine series’ base to modern standards. Especially given the rumors over the next gen Intel CPU’s being even bigger.

By the same token we are indeed glad to see that Arctic has once again opted for a more modern approach to CPU cooling solution. First and foremost, they are just plumb better and more efficient than the older rectangular block style they used to be back in the LGA 11×0 days. Here is a photo comparing the Alpine 17 LP (obviously on the left), and the bog standard Alpine 11 (obviously on the right).

It is blatantly obvious that the older Alpines took a rectangular hunk of aluminum and using a 5-axis vertical mill CNC machined it in a few steps. That is why the fins are relatively thick, they are directional, and there is not all that many of them. Furthermore, the base of the older Alpines was extremely thick. The new generation is using either wire EDM or laser cutting manufacturing process. Basically, this change to a much, much more expensive process means that Artic can start with a long extruded aluminum round bar, slice off chunk, mill in the base (as seen by the milling marks on the edges of it), do a touch off pass around the edge to ensure it is perfectly 95mm round, then laser cut the fins into said aluminum… annnnnd its done

This change not only means a faster manufacturing process but results in better cooling potential. Remember with fin arrays it is all about surface area and (most likely) laser cutting allows for extremely thin (and numerous) fin arrays with a more complicated design. This not only allows for better static pressures (i.e. the fan does not have to work nearly as hard), massive gains in surface area, but also allows for full 360 air flow movement over the motherboard. Thus everything from the motherboard VRM heatsinks, the RAM, and even M.2 SSD heatsinks can get cooled. Something previous Alpine gen’s could not do.

It also allows for a bigger fan to be used. After all, with a rectangular fin array the fan can not really be bigger than the narrowest dimensions… lest all the air movement skip the fin array and flow down the outside ‘long’ edges. This is why Artic can easily use an 95mm fan. Interestingly enough, they do not call nor classify it as a 95mm fan. Instead Artic states it is an ‘88mm’ fan. This is technically true if you measure from blade tip to blade tip. Personally we would classify this is a 92mm fan that is using a custom 95mm fan housing.

In either case the “88mm” fan is labeled as an “Alpine 17”… but obviously shares a common ancestor with both the Artic F series and the Arctic Slim P series of fans. Like the F series the Alpine 17 fan uses a fluid dynamic bearing (and not sleeve like the Slim P series); however, the RPMs (300-3000) share more in common with the P Slim series (300-2100) rather than the F series (400-1800). Also (somewhat) like the P Slim series, this new fan uses a larger number of smaller blades compared to the F series. However, unlike the typical P92 series which uses seven fans, the Alpine 17 makes use of ten. Unlike either series the Alpine 17 fan is neither slim (15mm) nor standard (25mm) thickness. Instead it is ~21.5mm thick.

As such this is best considered a new hybrid design that is intended to take on the “80mm” fan Intel uses in their R series… and beat it. Which it handily does in the noise, cooling, and even aesthetics departments. The only area where it loses out to the Intel R series 80mm fan is in the static pressure department. Which makes sense as the R’s fan was basically designed around the ~70mm tall RH1 and then modified for the RM and RS variants… so yes. It needed all the static pressure it could get.

However, this improved torque in Intel R cooler’s fan comes at the expense of noise. The difference between the Alpine 17LP and Intel R series is especially noticeable when they are all running flat-out. While the Alpine 17 LP’s noise is mostly wind noise, the RS and RM’s have a terrible high pitched hum and sometimes even a whistling sound profile. The former of which comes from the torquier fan hub, and the latter comes from a poor implementation of Laminar flow air movement. An idea which can indeed improve results (as seen by the RH1’s abilities)… but only when implemented properly. Certainly not when it comes at the cost of surface area of the fin array and fan size available. Both of which describe the RS1 and RM1 to a ‘t’.

To be perfectly blunt, when you work with those coolers in a couple builds and then use the RH1 it becomes blatantly obvious that the RS1 and RM1 were mere afterthoughts and the design team put all their time, effort, and budget into making the RH1 a good stock cooling solution. Thankfully Artic is there to take up the slack with optimized designs and optimized form-factors.